Pyrometallurgical services

Low-Temperature heat treatment

Low-temperature techniques in heat treatment and metallurgy include physical and chemical processes taking place at high temperatures but below the melting point.

A major part of our day-to-day activities includes low temperature heat treatment processes of raw materials, by-products, industrial wastes, alloys etc. The goal of these processes is the physical and/or chemical modification of the raw materials (e.g., removing impurities or volatile substances, incurring thermal decomposition, and improving reactivity, porosity, and crystallinity etc.).

Our services include:

- Calcination

- Microwave-assisted calcination

- Oxidizing roasting

- Reduction roasting

- Chlorination roasting

- Sulfidation roasting

- Microwave-assisted roasting

In our laboratory, we have the following pyrometallurgical equipment installed:

- Muffle furnace

- High-Temperature Muffle furnace

- Tube furnace

- Vacuum graphite furnace

- Rotary kiln

- Microwave rotary kiln

- Static microwave furnace

- Fluidized bed reactor

- Thermogravimetric furnace

High-Temperature heat treatment

High-temperature techniques in heat treatment and metallurgy include physical and chemical processes taking place at temperatures above the melting point.

A major part of our day-to-day activities includes high-temperature heat treatment processes of raw materials, by-products, industrial wastes, alloys etc. These processes aim either at the production (from primary or secondary raw materials), purification and alloying of metals at the molten state.

Our services include:

- Melting of metals and alloys

- Alloy synthesis

- Reductive or Oxidizing Smelting

We support these services by the following equipment installed in our facilities:

Electric arc furnace (80 kWA)

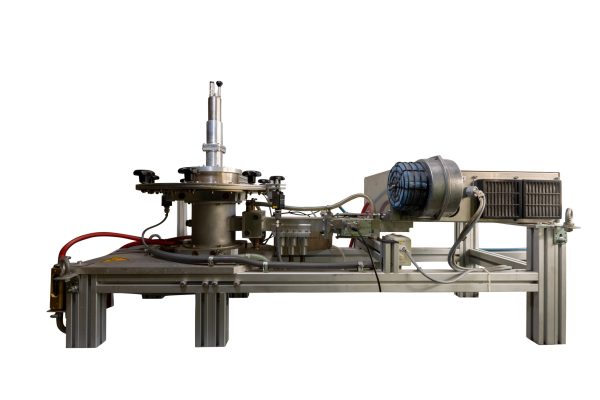

Induction vacuum furnace

High- Temperature muffle furnace

Vacuum graphite furnace