Hydrometallurgical services

Solid/liquid extraction services

Our deep knowhow and long experience in hydrometallurgical processes, allows us to perform diverse, cutting-edge research in the extraction of metals from raw materials, by-products, industrial wastes, alloys etc.

We can develop and perform:

Batch and semi-continuous hydrometallurgical extraction tests, tailored to any raw material

In lab-scale and pilot scale capacity

Dedicated kinetic and thermodynamic studies

Process intensification and modelling in base, reactive and rare metal systems

Our hydrometallurgical extraction equipment covers all the major hydrometallurgical operations, including:

Alkaline leaching in caustic solutions (Inconel and Stainless-steel vessels)

Acid leaching in all mineral acid systems (Titanium, Glass-lined and Glass vessels)

- Pressure leaching (for both alkaline and acid systems)

Oxidative and Reductive leaching with gases (N2, O2, H2S, CO, NH3 etc.)

Microwave assisted leaching

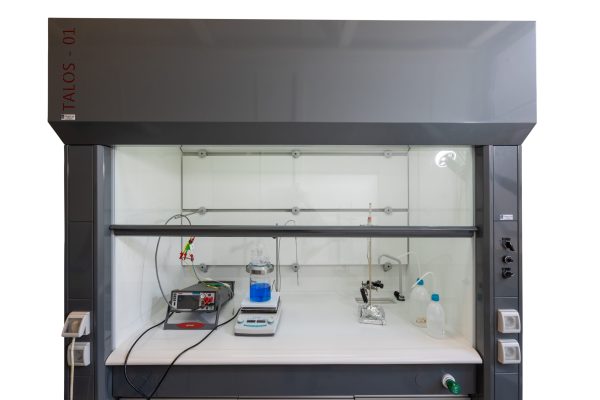

Our equipment comes with advanced monitoring capabilities (conductivity, pH, gas analyzers and sensors, radioactivity sensors, etc.) and we can perform:

Extraction tests in aggressive conditions (high concentration of reagents, with strong acids and bases, at increased temperatures and pressures)

Tests with hazardous materials and/or wastes, both in the solid and liquid state

Purification services

Hydrometallurgical purification processes is one of the pillars of our research and development activities. We have worked with a wide variety of raw materials, by-products, industrial wastes, alloys etc.

These processes are critical due to the increasing demand for high-purity metals and the need to exploit complex metal deposits and recover valuable metals from industrial wastes or by-products.

Our research experience includes but is not limited to:

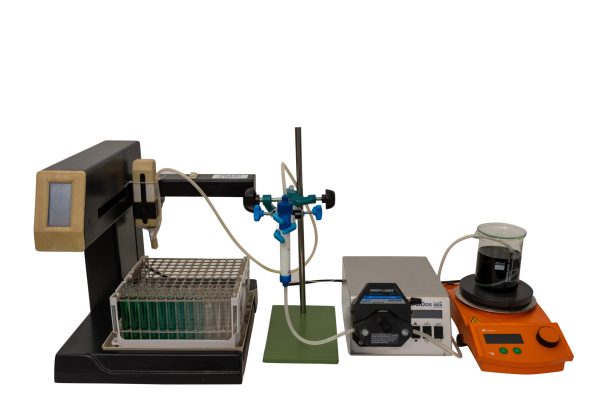

- Ion exchange separation

- Solvent extraction separation

- Membrane separation

- Precipitation

- Anti-solvent precipitation

We are developing innovative techniques that help our partners increase efficiency, reduce environmental impact and improve the purity and properties of their products. Some of the basic purification equipment we employ are:

- Mixing settlers

- Separating funnels

- Ion exchange columns

Electrometallurgical services

The electrification of metallurgical processes is a major research and innovation activity in our group. We perform electrometallurgical research and develop electrochemical techniques to treat solid or liquid raw materials, by-products, industrial wastes, alloys etc.

Our expertise includes but is not limited to:

Potential-controlled techniques (Chronoamperometry, Chronocoulometry, Cyclic Voltammetry, Linear Sweep Voltammetry)

Current-control techniques (Chronopotentiometry, Galvanodynamic curve)

Metal corrosion studies

Electroanalytical methods

Keeping up with our experimental needs and research activities, our electrochemical equipment includes, among others, the following:

Versastat 3 Potentiostat Galvanostat (Princeton Applied Research)

Keithley Potentiostat 2461-EC (10 A – 100 V)

Gamry corrosion cell kit

Electrodialysis cell

Electrochemical cells from 80 to 500 ml

Autoclave cell for electrochemical experiments in extreme experimental conditions (high temperature, high pH)

Rotary barrel electroplating cell

Rotary barrel electrorefining cell